overview

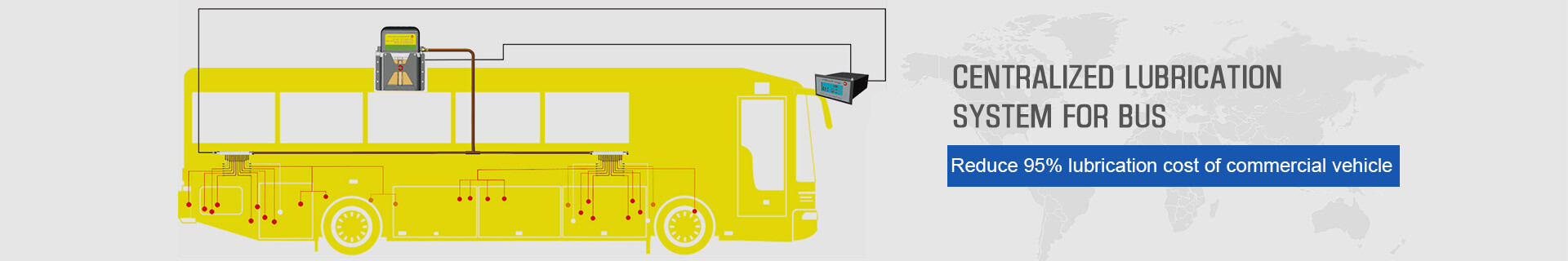

To provide lubrication solution for varied cars and buses. Autol can design suitable lubrication solution for each customer’s specific needs.

Chat nowAdvantages of centralized lubrication system:

1. Automatic system guarantees timing and automatic lubrication, which saves labor (95%) and ensures operators’ safety.

2. Longer truck life, expand your machines’ lifespan for more than 60%

3. Save grease for more than 70%, environmentally sustainable

Working principle:

The system is controlled by ECU to make sure the cycle work of the gear pump.When the system works, the motor drives the gear pump to work, sucking and delivering the lube. After the lube is pressed into the supply line, it is delivered to all the lube points through the single-line distributor(pressure-type distributor). The system releases pressure after the operation.