overview

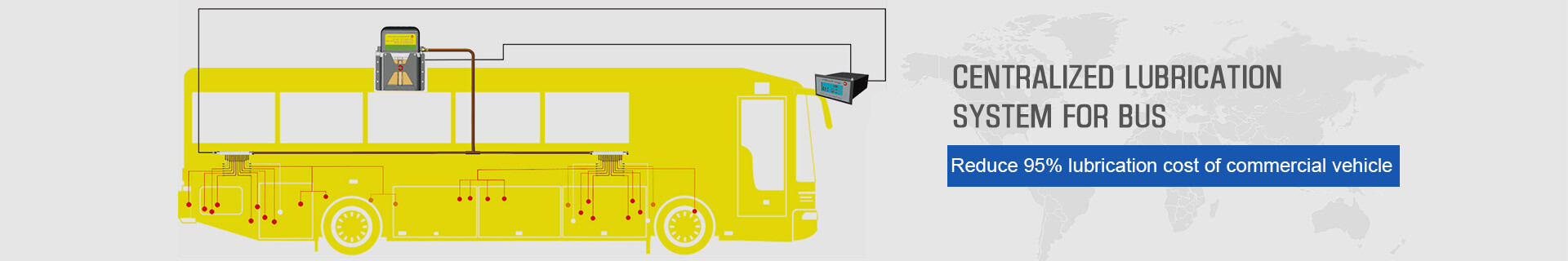

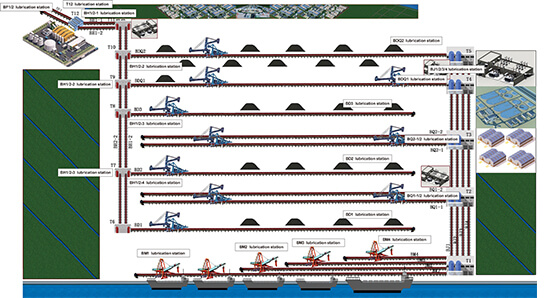

The centralized lubrication system developed by Auto Technology remotely monitors the operation condition of each lubrication station in real-time and provides good lubrication solution for port heavy machinery.

Chat nowPurpose:

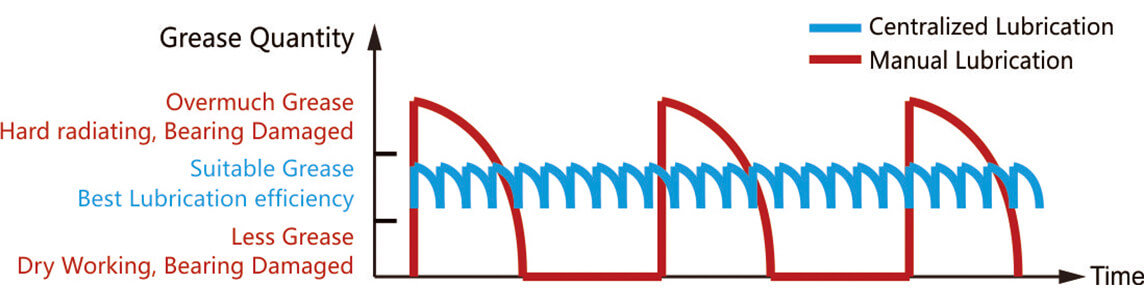

Due to considerable power, friction factor and impact load, the belt conveyor in ports is easily abraded, which requires the precision and safety of its lubrication. We equip the belt conveyor in ports with lubrication system with efficient operation data.

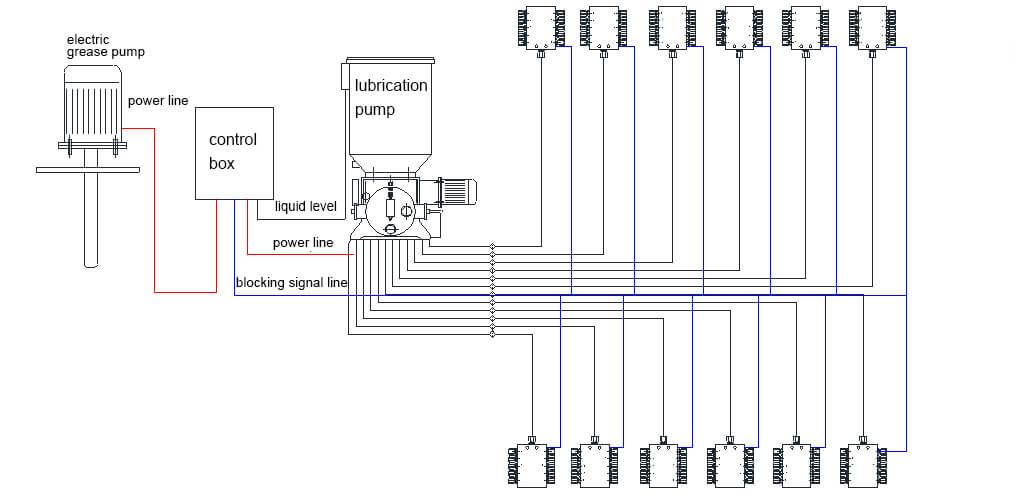

Working Principle:

The remote monitoring and controlling computer keeps wireless communication with each lubrication station, collecting and classifying the lubrication data of each. If any fault appears, the remote monitoring computer and control box can localize it specifically.

System Analysis:

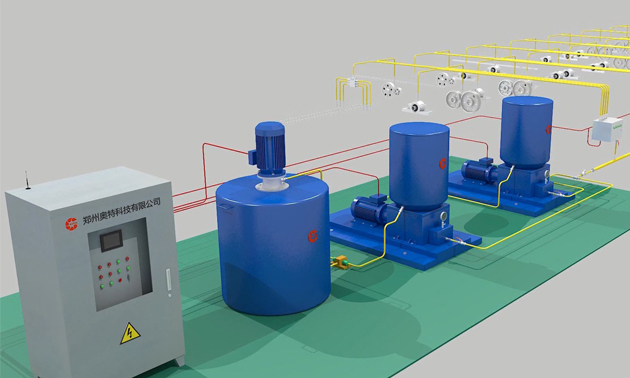

The system consists of monitoring and lubrication systems. The lubrication system is composed of electric control box, electric lubrication pump, oil feeding pump, filter, distributor, pipe, sensor and accessories. The monitoring system is made up of remote monitoring and controlling computer, monitoring software, communication module and electric control box(with communication module). The details are as following chart.

| Serial | Part Name | Model | Supplier | Quantity | Unit |

| 1 | monitoring master station | AK2000A | Zhengzhou Autol | 1 | unit |

| 2 | monitoring substation | AK2000B | Zhengzhou Autol | 1 | unit |

| 3 | monitoring software | AM1200K | Zhengzhou Autol | 1 | set |

Autol Intelligent Centralized Lubrication System

With computer, automatic control, wireless data transmission and centralized lubrication technology, this system is a new intelligent solution characterized with smart centralized management, remote online monitoring and environmental protection. Compared to timing lubrication with fixed quantity, this system supplies lube with an improved model which is distribution by needs with appropriate quantity at proper time. Besides, the pump ability has been improved.

Advantages:

Wireless remote control

smart monitoring and controlling

supplying oil for multiple points

safety, energy-saving and environmental protection.

Lubrication Station Solution(a specific case to illustrate its configuration)

For the 27 belt conveyors, there are 25 lubrication stations, of which 20 is automatic stations and 5 manual ones. Automatic stations include BF1/2, BH1/2-1, BH1/2-2, BH1/2-3, BH1/2-4, BQ1-1/2, BQ2-1/2, BJ1/2/3/4, BM3, BM1/2, BH1/2-2, BH1/2-3, BDQ1, BDQ2, BD1, BD2, BD3, BM4, T1, T12, etc. Manual stations are T2, T3, T4, T5, T11, etc.

The configuration of BF1/2

The configuration of BF1/2

| Serial |

Name |

Model | Quantity |

| 1 | Electric lubrication pump(pump cap) | P215 | 1 |

| 2 | Control box | ATK02 | 1 |

| 3 | Electric oil feeding pump | DJB-F200 | 1 |

| 4 | distributor | SSV10 | 12 |

| 5 | Supply line(stainless) |

Φ22X2 |

210 |

| 6 | filter |

/ |

12 |

| 7 | Feed line(stainless) |

Φ10X1 |

260 |

| 8 | Ferrule direct connector |

Φ10 |

20 |

| 9 | Ferrule taper pipe connector |

/ |

150 |

| 10 | Single pipe clamp |

φ10 |

60 |

| 11 | Double pipe clamp |

φ10*2 |

60 |

| 12 | Triple pipe clamp |

φ10*3 |

60 |

| 13 | five- pipe clamp |

φ10*5 |

20 |

| 14 | Steel pipe connector |

φ22 |

4 |

| 15 | Metal pipe |

φ22 |

15 |

| 16 | High-pressure pipe | 1m | 60 |

| 17 | Control cable | RVVP3*1.0 | 160 |

| 18 | Power cable | 3*2.5+1.5 | 10 |

| 19 | Pipe strap |

φ18 |

25 |

| 20 | Direct connector |

/ |

15 |

| 21 | protective cover |

/ |

12 |

| 22 | protection box |

/ |

1 |

| 23 | threading pipe(stainless) |

Φ22X1 |

160 |

Some Components of the System

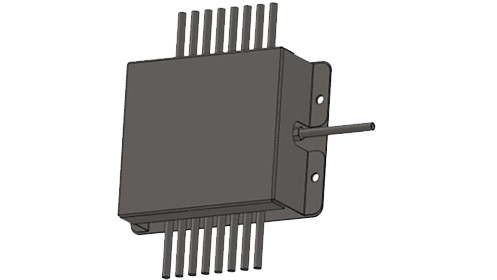

1. Progressive Distributor

Technical parameters:

Max Pressure: 300bar

Output: 0.2ml/cy

Working Temperature: -30—80℃

The Max Pressure Difference Between 2 Outlets: 150bar

Lube: NLGI 0#、1#、2#、3#

Description: The distributor is equipped with anti-pulverized coal and salt and fog protective cover(stainless 316L).

2. Filter

Function: To filter the lube in supply lines

3. High-pressure Hose

Technical parameters:

Pressure: 40MPa

Brand: Xiangsi

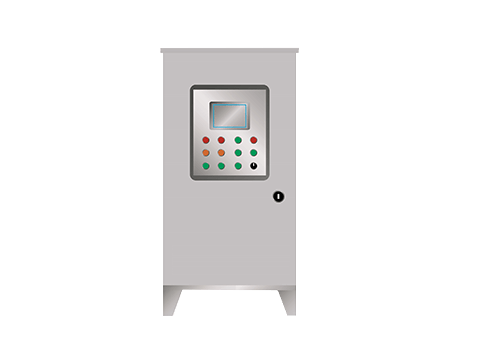

4. Control Box

Through remote monitoring system and display screen, to set operation parameters, monitor the liquid level signal and the working condition of the lubrication pump, and give an alarm then faults appear.

Technical parameters:

Power: AC380V 50Hz

Control Mode: Auto/ Manual

Alarm Signal: liquid level, blockage

Communication Mode: RS485/ wireless

Supply cycle: 1-99h

Supply time: 1-99m

5. Oil Feeding Pump

Main Technical parameters:

Nominal Pressure: 2.5MPa

Oil supply: 200L/h

Motor Power: 1.1KW

It can be directly applied to 180kg oil tank.

6. The protective cover of distributor

Material : stainless 316L

Shape and dimension: 200*160*60

Each distributor is equipped with a protective cover which is connected with bolts to ensure taht is is easy to maintain and operate.

Autol's Lubrication

1. Customize proper and reliable lubrication solution according to customers' needs.

2. Design the lube supply for each lubrication point according to each one's specific need.

About autol

Quality Control

With strict quality control system and quality standards, our company ensures the products’ quality.

Service

1.Customized lubrication solution for each specific excavator.

2.Training on the operation and maintenance of the system for customers.

3.Installation and adjustion of the equipment to ensure its operation.

4.For the products out of warranty, we provide lifetime maintenance. And as for the spare parts used, we will charge by unified standard.

5.We provide common easily-worn parts which costs 3% of your buying.

Packaging

Carton and wooden case

To ensure the products are easy to transport, packing can be flexible according to needs.

About us

Products

Contact us

© 2016 Zhengzhou Autol Technology Co.,Ltd. All Rights Reserved.