overview

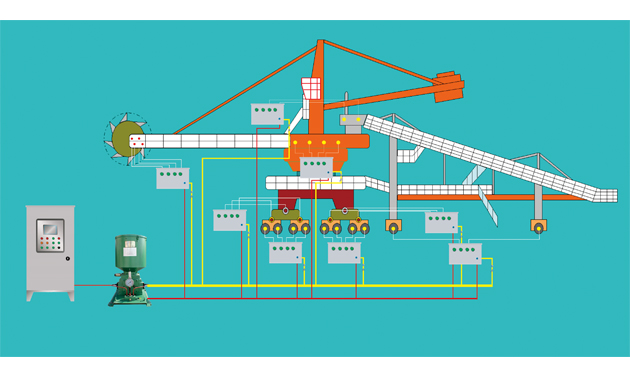

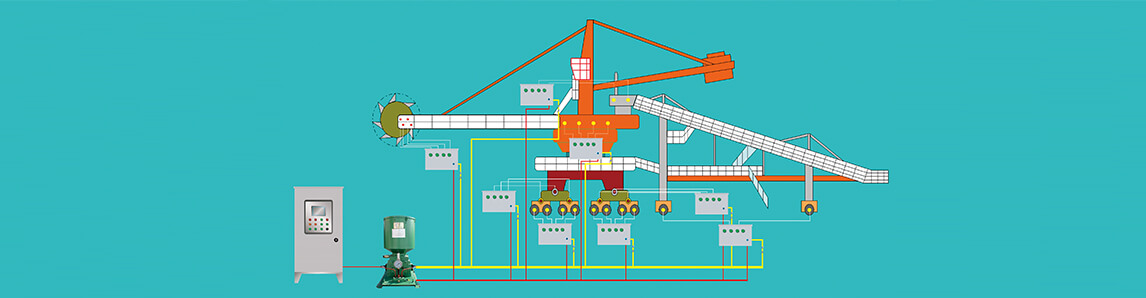

In the material system of blast furnace plant, bucket wheel machine is a key equipment, which can affect the production of blast furnace plant. To reduce abrasion and power loss, lengthen its lifespan, we lubricate the bucket wheel machine.

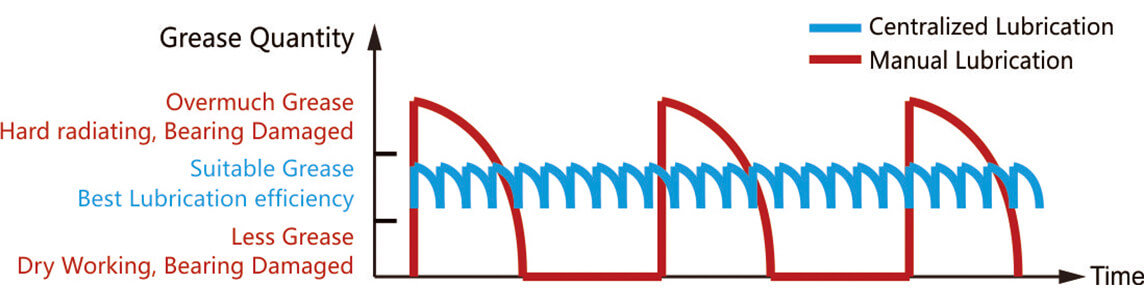

Chat nowThe advantages of centralized lubrication system over manual lubrication:

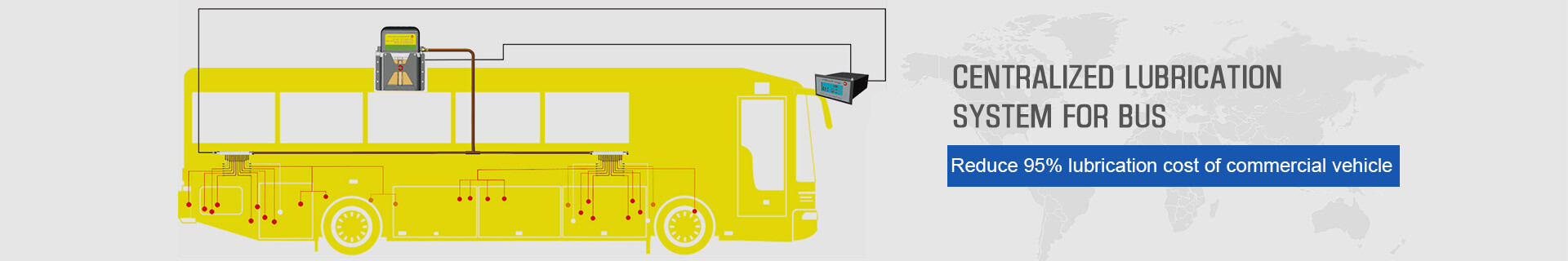

1. Automatic system guarantees timing and automatic lubrication, which saves labor (95%) and ensures operators’ safety.

2. By forced and timing lubrication with fixed quantity for fixed points, centralized lubrication system is clean and grease-saving. Save grease for more than 70%, environmentally sustainable.

The advantages of centralized lubrication system over manual lubrication:

3. Compared to manual lubrication, centralized lubrication system is enclosed, which avoids grease leaking and the abrasion of friction pairs.

4. Your machine is well greased, which extends the service interval, thus lengthening working time and enchancing your efficiency.

5. Expand your machines’ lifespan for more than 60%.

System Analysis:

Autol Intelligent Centralized Lubrication System

With computer, automatic control, wireless data transmission and centralized lubrication technology, this system is a new intelligent solution characterized with smart centralized management, remote online monitoring and environmental protection. Compared to timing lubrication with fixed quantity, this system supplies lube with an improved model which is distribution by needs with appropriate quantity at proper time. Besides, the pump ability has been improved.

Advanced Technologies:

Online monitoring: collect, inquire and store the data of the system; give a fault alarm, find the operation failure, provide fault analysis, eliminate fault to make sure the system efficient, safe and convenient.

With automatic controlling technology, the pump can supply lube automatically and efficiently.

By monitoring each lube points, the system can precisely adjust the operation diameters which guarantees environmental and saving lube distribution by needs with appropriate quantity at proper time.

The integration of network, automation, sensing technology and lube system makes sure the equipment work well. If anything goes wrong, the system will find and address promptly to avoid equipment damage.

Components

PLC, pumps, solenoid directional valve, smart distributor, pipe and accessories, monitoring and controlling system, etc.

1.Programmable Logic Controller(PLC)

PLC controls the electric elements of the lube system by programming. The data of the PLC can be displayed by touch screen

Provide DC24V, AC380V, AC220V 50Hz electricity;

Adjust supply parameters and display the system;

Control grease station and protect the system;

Control model: automatic and manual operation

Alarm signals: high or low liquid level, block, leakage, fault

Communication method: RS-485

Supply cycle:adjustable

Supply time:adjustable

Supply volume:adjustable

Material: stainless

Style: double-door, enclosed type, rain-proof and dust-proof

2.Electronic Oil Feeding Pump

When the oil level in the lube pump is low, PLC will send start signal to the oil feeding pump and it starts feeding the lube pump till the high liquid level.

Main Technical Parameters:

Nominal pressure: 2.5 MPa

Output: 200 L/h

Capacity: 270 L

Power: 1.1kw

Voltage: AC380V

Operating temperature: 20℃~+100℃

Lube: NLGI 0 #-2#

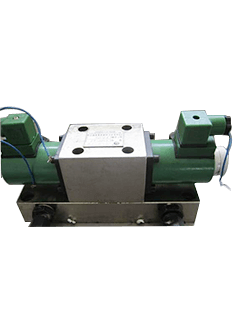

3.Solenoid Directional Valve

Through solenoid directional valve, the oil feeding pump can feed the lube pump with automatic direction change.

Main Technical Parameters:

1. Nominal pressure: 20 MPa

2. Power: 30W

3. Max Output: 3 L/min

4. Direction change frequency: 30 times/min

5. Operating temperature: 0-50℃

4.Intelligent Distributers

In the system, intelligent distributer carries out the last step of the lubrication. Receiving the signal sent by PLC, the smart distributer controls the solenoid valve to move so that there is a path between supply line and lube points, which makes it possible for the lube to be delivered to lube points. Meanwhile, the distributer collects the signals of the flowmeter, send them to PLC, which makes sure data collection and problem solving.

Components: smart controller, volumetric flowmeter, solenoid oil feeder, pipe, tie,etc.

Advantages:

1. Volumetric flowmeter monitors the supply of each point on real time, avoiding the bad effects made by pressure, distance and temperature, etc.

2. Double controlling modes can avoids failure better than one controlling mode.

3. The working condition of the system can be seen through smart controller, which is convenient for fault inquiry.

4. Smart controller can control each solenoid valve, which is convenient for fault inquiry and problem solving.

Main Technical Parameters:

1. Electricity: DC24V

2. Outlet number: 3--5

3. Communication method: RS-485

5.Pipe and Accessories

Supply line

Through supply lines, an electronic pump delivers high-pressured lube to the inlets of each distributors.

Main Technical Parameters:

1.Material: stainless

2.Outside diameter: Φ32mm

3.Thickness: 3mm

Feed line

Feed line is the lube carrier from smart distributer to lube points.

Main Technical Parameters:

1. Material: stainless

2. Outside diameter: Φ10mm

3. Thickness: 1.5mm

6.Filter

By filtering the impurity in delivered lube, a filter avoids the blockage in solenoid valve. Main Technical Parameters:

1. Grease: NLGI0#-2#

2. Filter Precision: 120μm

3. Working Temperature: below 120℃

4. Nominal Pressure: 40MPa

Parameters

| Serial |

Name |

Model |

| 1 |

Max number of lube points |

1~1275 points |

| 2 |

Max number of smart distributers |

1~255 |

| 3 |

Outlet number of smart distributers |

1~5 |

| 4 |

Nominal pressure of lube pump |

0~40MPa adjustable |

| 5 |

Working voltage |

AC380V/220V 50Hz |

| 6 |

Controlling voltage |

DC24V |

| 7 |

power |

5KW |

| 8 |

Grease |

NLGI——1#~2# |

| 9 |

Operation mode |

automatic/manual /sudden stop |

| 10 |

Operation temperature |

-20~100℃ |

| 11 |

outlet volume per time |

adjustable |

| 12 |

Supply time per time |

adjustable |

| 13 |

interval time between cycles |

adjustable |

| 14 |

Communication |

RS-485 bus |

| 16 |

Fault alarm |

text display |

About autol

Quality Control

With strict quality control system and quality standards, our company ensures the products’ quality.

Service

1.Customized lubrication solution for each specific excavator.

2.Training on the operation and maintenance of the system for customers.

3.Installation and adjustion of the equipment to ensure its operation.

4.For the products out of warranty, we provide lifetime maintenance. And as for the spare parts used, we will charge by unified standard.

5.We provide common easily-worn parts which costs 3% of your buying.

Packaging

Carton and wooden case

To ensure the products are easy to transport, packing can be flexible according to needs.

About us

Products

Contact us

© 2016 Zhengzhou Autol Technology Co.,Ltd. All Rights Reserved.